316 Stainless Steel Tube Fittings Male Connector

MC

Instrument Fittings

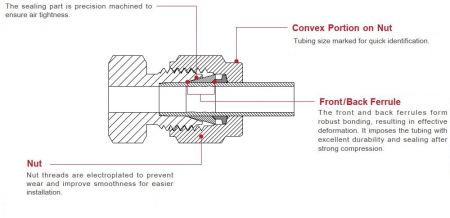

The 316 stainless steel Male Connector (MC) is designed for leak-free, reliable connections in high-pressure applications. Featuring a double-ferrule design, this fitting ensures secure tube sealing while resisting corrosion, wear, and extreme conditions. Ideal for instrumentation, chemical, medical, and industrial piping systems.

Ordering & Customization:

Standard sizes available for immediate shipment

Custom sizes and OEM/ODM services available

Minimum order quantity (MOQ) and lead time available on request

For quotes, please contact us through the inquiry form below

Features

- Material: 316 Stainless Steel for excellent corrosion resistance and durability

- Design: Double-ferrule metal-to-metal sealing for leak-free performance

- Thread Options: PT, NPT, M, or PF to meet diverse standards

- Installation: Simple, reliable installation without special tools

- Range: Compatible with a wide variety of tube outer diameters (O.D.)

- Finish: Electroplated nut threads for enhanced wear resistance

Technical Data

Working Pressure:

(1) 1/2 inch (12mm) Below: 210 kgf/cm²

(2) 3/4 inch (19mm) Above: 100 kgf/cm²

Suitable Tube O.D.: 1/8 ~ 1 inch ; 3 ~ 20mm

Thread: PT, NPT, M

Note: Available in both metric and imperial sizes. Custom sizes can be provided upon request.

Application

- Instrumentation and measurement systems

- Chemical and pharmaceutical piping

- Water treatment and fluid systems

- Food and beverage processing

- Petrochemical and industrial pipelines

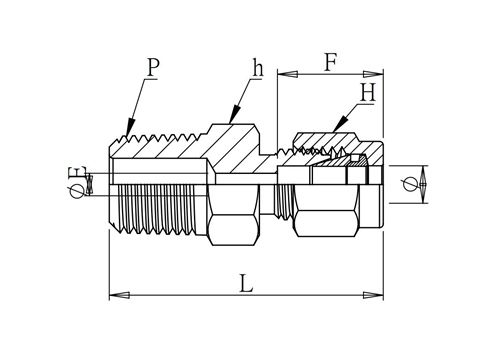

Dimension

Specification

MC Tube Fittings Male Connector-PT| Part No | Tube OD | Thread Size | Dimensions | H |  | ||

|---|---|---|---|---|---|---|---|

| Ø | P-PT | Ø E | F | L | |||

| MC03M03T | 3 | 1/8" | 2.4 | 12.8 | 30.6 | 12 | 12 |

| MC03M06T | 1/4" | 35.1 | 14 | ||||

| MC04M03T | 4 | 1/8" | 2.5 | 13.8 | 31.8 | 12 | 12 |

| MC04M06T | 1/4" | 36.3 | 14 | ||||

| MC06M03T | 6 | 1/8" | 4.8 | 15.5 | 34 | 14 | 14 |

| MC06M06T | 1/4" | 37.8 | |||||

| MC06M10T | 3/8" | 38.8 | 17 | ||||

| MC06M15T | 1/2" | 43.8 | 22 | ||||

| MC08M03T | 8 | 1/8" | 4.8 | 16.2 | 34.4 | 16 | 14 |

| MC08M06T | 1/4" | 6.4 | 38.4 | ||||

| MC08M10T | 3/8" | 39.4 | 17 | ||||

| MC08M15T | 1/2" | 44.4 | 22 | ||||

| MC10M03T | 10 | 1/8" | 4.8 | 17.2 | 36.5 | 19 | 17 |

| MC10M06T | 1/4" | 7 | 39.5 | ||||

| MC10M10T | 3/8" | 8 | 40.5 | ||||

| MC10M15T | 1/2" | 45.5 | |||||

| MC12M03T | 12 | 1/8" | 4.8 | 23 | 39.5 | 22 | 21 |

| MC12M06T | 1/4" | 7 | 42.5 | ||||

| MC12M10T | 3/8" | 9.7 | 43.5 | ||||

| MC12M15T | 1/2" | 48.5 | 22 | ||||

| MC12M20T | 3/4" | 51.5 | 27 | ||||

| MC14M15T | 14 | 1/2" | 11 | 23.3 | 48.3 | 24 | 22 |

| MC15M10T | 15 | 3/8" | 9.7 | 25.3 | 45.5 | 24 | 22 |

| MC15M15T | 1/2" | 12 | 49.5 | ||||

| MC15M20T | 3/4" | 51.5 | 27 | ||||

| MC16M15T | 16 | 1/2" | 12 | 24.9 | 49.1 | 27 | 24 |

| MC16M20T | 3/4" | 12.7 | 52.1 | 27 | |||

| MC18M15T | 18 | 1/2" | 12 | 24.8 | 50 | 30 | 27 |

| MC18M20T | 3/4" | 15 | 52 | 27 | |||

| MC20M15T | 20 | 1/2" | 12 | 26.5 | 49.5 | 32 | 30 |

| MC20M20T | 3/4" | 16 | 51.5 | ||||

| MC22M15T | 22 | 1/2" | 12 | 26.5 | 49.5 | 36 | 30 |

| MC22M20T | 3/4" | 16 | 51.5 | ||||

| MC25M15T | 25 | 1/2" | 12 | 30.7 | 53.7 | 38 | 35 |

| MC25M20T | 3/4" | 16 | 56.2 | ||||

| MC25M25T | 1" | 22 | 58.2 | ||||

| Part No | Tube OD | Thread Size | Dimensions | H |  | ||

|---|---|---|---|---|---|---|---|

| Ø | P-PT | Ø E | F | L | |||

| MC10I03T | 1/8" | 1/8" | 2.4 | 13.2 | 31 | 12 | 12 |

| MC10I06T | 1/4" | 35.5 | 14 | ||||

| MC15I03T | 3/16" | 1/8" | 3 | 14.1 | 32 | 12 | 12 |

| MC15I06T | 1/4" | 36.5 | 14 | ||||

| MC20I03T | 1/4" | 1/8" | 4.8 | 15.5 | 34 | 14 | 14 |

| MC20I06T | 1/4" | 37.8 | |||||

| MC20I10T | 3/8" | 38.8 | 17 | ||||

| MC20I15T | 1/2" | 43.8 | 22 | ||||

| MC30I03T | 3/8" | 1/8" | 4.8 | 17.2 | 36 | 17 | 16 |

| MC30I06T | 1/4" | 7 | 39 | ||||

| MC30I10T | 3/8" | 40 | 17 | ||||

| MC30I15T | 1/2" | 45 | 22 | ||||

| MC40I03T | 1/2" | 1/8" | 4.8 | 23 | 39.5 | 22 | 21 |

| MC40I06T | 1/4" | 7 | 42.5 | ||||

| MC40I10T | 3/8" | 9.7 | 43.5 | ||||

| MC40I15T | 1/2" | 10.5 | 48.5 | 22 | |||

| MC40I20T | 3/4" | 51.5 | 27 | ||||

| MC50I15T | 5/8" | 1/2" | 12 | 24.9 | 49.1 | 27 | 24 |

| MC50I20T | 3/4" | 12.7 | 52.1 | 27 | |||

| MC60I15T | 3/4" | 1/2" | 12 | 24.6 | 49.8 | 28.6 | 27 |

| MC60I20T | 3/4" | 51.8 | |||||

| MC60I25T | 1" | 56.8 | 35 | ||||

| MC80I15T | 1" | 1/2" | 12 | 30.8 | 53.8 | 38 | 35 |

| MC80I20T | 3/4" | 16 | 56.3 | ||||

| MC80I25T | 1" | 22 | 58.3 | ||||

| Part No | Tube OD | Thread Size | Dimensions | H |  | ||

|---|---|---|---|---|---|---|---|

| Ø | P-NPT | Ø E | F | L | |||

| MC03M03N | 3 | 1/8" | 2.4 | 12.8 | 30.6 | 12 | 12 |

| MC03M06N | 1/4" | 35.1 | 14 | ||||

| MC04M03N | 4 | 1/8" | 2.5 | 13.8 | 31.8 | 12 | 12 |

| MC04M06N | 1/4" | 36.3 | 14 | ||||

| MC06M03N | 6 | 1/8" | 4.8 | 15.5 | 34 | 14 | 14 |

| MC06M06N | 1/4" | 37.8 | |||||

| MC06M10N | 3/8" | 38.8 | 17 | ||||

| MC06M15N | 1/2" | 43.8 | 22 | ||||

| MC08M03N | 8 | 1/8" | 4.8 | 16.2 | 34.4 | 16 | 14 |

| MC08M06N | 1/4" | 6.4 | 38.4 | ||||

| MC08M10N | 3/8" | 39.4 | 17 | ||||

| MC08M15N | 1/2" | 44.4 | 22 | ||||

| MC10M03N | 10 | 1/8" | 4.8 | 17.2 | 36.5 | 19 | 17 |

| MC10M06N | 1/4" | 7 | 39.5 | ||||

| MC10M10N | 3/8" | 8 | 40.5 | ||||

| MC10M15N | 1/2" | 45.5 | |||||

| MC12M03N | 12 | 1/8" | 4.8 | 23 | 39.5 | 22 | 21 |

| MC12M06N | 1/4" | 7 | 42.5 | ||||

| MC12M10N | 3/8" | 9.7 | 43.5 | ||||

| MC12M15N | 1/2" | 48.5 | 22 | ||||

| MC12M20N | 3/4" | 51.5 | 27 | ||||

| MC14M15N | 14 | 1/2" | 11 | 23.3 | 48.3 | 24 | 22 |

| MC15M10N | 15 | 3/8" | 9.7 | 25.3 | 45.5 | 24 | 22 |

| MC15M15N | 1/2" | 12 | 49.5 | ||||

| MC15M20N | 3/4" | 51.5 | 27 | ||||

| MC16M15N | 16 | 1/2" | 12 | 24.9 | 49.1 | 27 | 24 |

| MC16M20N | 3/4" | 12.7 | 52.1 | 27 | |||

| MC18M15N | 18 | 1/2" | 12 | 24.8 | 50 | 30 | 27 |

| MC18M20N | 3/4" | 15 | 52 | 27 | |||

| MC20M15N | 20 | 1/2" | 12 | 26.5 | 49.5 | 32 | 30 |

| MC20M20N | 3/4" | 16 | 51.5 | ||||

| MC22M15N | 22 | 1/2" | 12 | 26.5 | 49.5 | 36 | 30 |

| MC22M20N | 3/4" | 16 | 51.5 | ||||

| MC25M15N | 25 | 1/2" | 12 | 30.7 | 53.7 | 38 | 35 |

| MC25M20N | 3/4" | 16 | 56.2 | ||||

| MC25M25N | 1" | 22 | 58.2 | ||||

| Part No | Tube OD | Thread Size | Dimensions | H |  | ||

|---|---|---|---|---|---|---|---|

| Ø | N-NPT | Ø E | F | L | |||

| MC10I03N | 1/8" | 1/8" | 2.4 | 13.2 | 31 | 12 | 12 |

| MC10I06N | 1/4" | 35.5 | 14 | ||||

| MC15I03N | 3/16" | 1/8" | 3 | 14.1 | 32 | 12 | 12 |

| MC15I06N | 1/4" | 36.5 | 14 | ||||

| MC20I03N | 1/4" | 1/8" | 4.8 | 15.5 | 34 | 14 | 14 |

| MC20I06N | 1/4" | 37.8 | |||||

| MC20I10N | 3/8" | 38.8 | 17 | ||||

| MC20I15N | 1/2" | 43.8 | 22 | ||||

| MC30I03N | 3/8" | 1/8" | 4.8 | 17.2 | 36 | 17 | 16 |

| MC30I06N | 1/4" | 7 | 39 | ||||

| MC30I10N | 3/8" | 40 | 17 | ||||

| MC30I15N | 1/2" | 45 | 22 | ||||

| MC40I03N | 1/2" | 1/8" | 4.8 | 23 | 39.5 | 22 | 21 |

| MC40I06N | 1/4" | 7 | 42.5 | ||||

| MC40I10N | 3/8" | 9.7 | 43.5 | ||||

| MC40I15N | 1/2" | 10.5 | 48.5 | 22 | |||

| MC40I20N | 3/4" | 51.5 | 27 | ||||

| MC50I15N | 5/8" | 1/2" | 12 | 24.9 | 49.1 | 27 | 24 |

| MC50I20N | 3/4" | 12.7 | 52.1 | 27 | |||

| MC60I15N | 3/4" | 1/2" | 12 | 24.6 | 49.8 | 28.6 | 27 |

| MC60I20N | 3/4" | 51.8 | |||||

| MC60I25N | 1" | 56.8 | 35 | ||||

| MC80I15N | 1" | 1/2" | 12 | 30.8 | 53.8 | 38 | 35 |

| MC80I20N | 3/4" | 16 | 56.3 | ||||

| MC80I25N | 1" | 22 | 58.3 | ||||

- Related Products

Stainless Steel Rapid Pneumatic Fitting Male Connector

VMC

Rapid pneumatic fittings are designed for fast, tool-free connection and disconnection of air lines,...

DetailsStainless Steel Rapid Pneumatic Fittings Female Connector

VFC

Rapid Pneumatic Fittings Female Connectors are widely used in liquid and gas tubing. It is suitable...

DetailsStainless Steel Rapid Pneumatic Fittings Union

VU

Rapid Pneumatic Fittings Unions made of 304 or 316 stainless steel are widely used in tubing...

DetailsStainless Steel Rapid Pneumatic Fittings Bulkhead Union

VBU

Rapid Pneumatic Fittings Bulkhead Unions are widely used in liquid and gas tubing. It is suitable...

DetailsStainless Steel Rapid Pneumatic Fitting Union Elbow

VUE

Rapid Pneumatic Fitting Union Elbows are widely used in liquid and gas tubing. It is suitable...

Details- Files Download

316 Stainless Steel Tube Fittings Male Connector (MC ) – CHIBIN Machine

Since 1980 in Taiwan, CHIBIN Machine makes 316 Stainless Steel Tube Fittings Male Connector —compression, push-in pneumatic, hydraulic, quick couplings, and precision nozzle and needle valves for medical and semiconductor use.

Our fittings are ISO-certified and TTQS-awarded, with MIL-STD-105E quality checks. We stock 10,000+ standard parts and offer OEM/ODM custom runs up to 3,000 pcs.

With advanced CNC manufacturing and 40+ years of experience, CHIBIN Machine meets tight specs for surface finish, thread standards, and leak-tight testing. Get a fast quote today.