Tube Technical Information

How to select tubes?

1. Hardness: Tubes are required to be soften than the fittings. For tubes and fittings made of the same material, the metal tubes shall be fully annealed for easy bending and flaring.

2. Surface: It's hard to seal if there are any scratches or defects on the surface of tube, particularly for gas system.

3. Roundness: Force inserting an elliptical or non-circular tube into the fittings may damage the sealing function of nut, ferrules and the body.

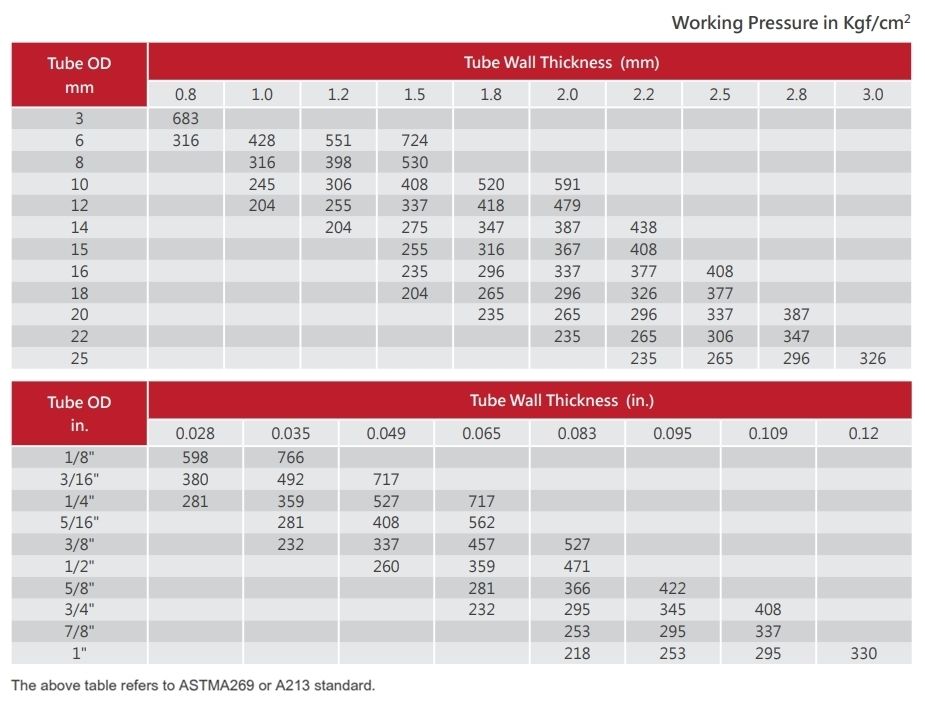

4. Tube thickness: Table below contains tube thickness and relevant range of working pressure. When ferrules are griping, too thin a tube wall tends to sag and deform and this is not the case for tubes of thicker wall.

DO NOT use tubes with wall thickness not available in the below table.

Safety precautions

1. DO NOT loosen or tighten the fittings when the system is left with pressure.

2. Please employ valid pressure relief method, such as pressure relief valve. DO NOT loosen the nut or plugs for pressure relief.

3. Make sure the tube stays firmly on the shoulder inside the fitting body before the tightening the nut.

4. Apply thread sealants or sealing tape on taper pipe thread (PT or NPT) to ensure the sealing effect.

5. It is recommended to use fittings of the same brand to prevent air leak due to different quality.

6. When removing and installing fittings, hold the fitting body steady and then rotate the nut.

7. DO NOT remove the nut of unused fittings to prevent collision of threads.

8. Hardness of stainless steel tube: less than or equal to 80HRB.