Quality

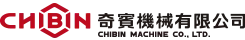

The company's Quality Management System is audited and certified to ISO9001-2015. Material analyzers are used to check the quality of raw materials as soon as they arrive, making sure they meet the specified standards.

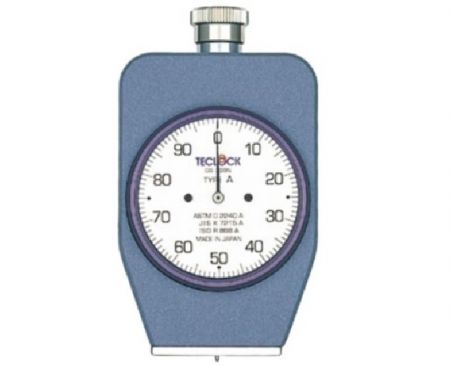

Our QC (quality control) team needs to perform random inspections on the production line every two hours. Additionally, the filed operator checks every 10 pieces on the production line.

Each and every one of our products gets a personal touch with manual deburring, and some of them need to get put together. When our assembly team is on it, they're not just slapping things together – they're also giving it a once-over for quality. All these steps make sure our products stick to the blueprints and meet the standards.

Any alternative testing requirements and test reports are also acceptable.